As devices continue to scale, so do process tolerances, driving the need for better accuracy and repeatability of measurements.

Whether used in the precise deployment of an airbag, the consistent rhythm of a pacemaker or simply for sharing life events on Facebook, technology trends are driving smarter, thinner and lighter electronics with more functionality than previous generations.

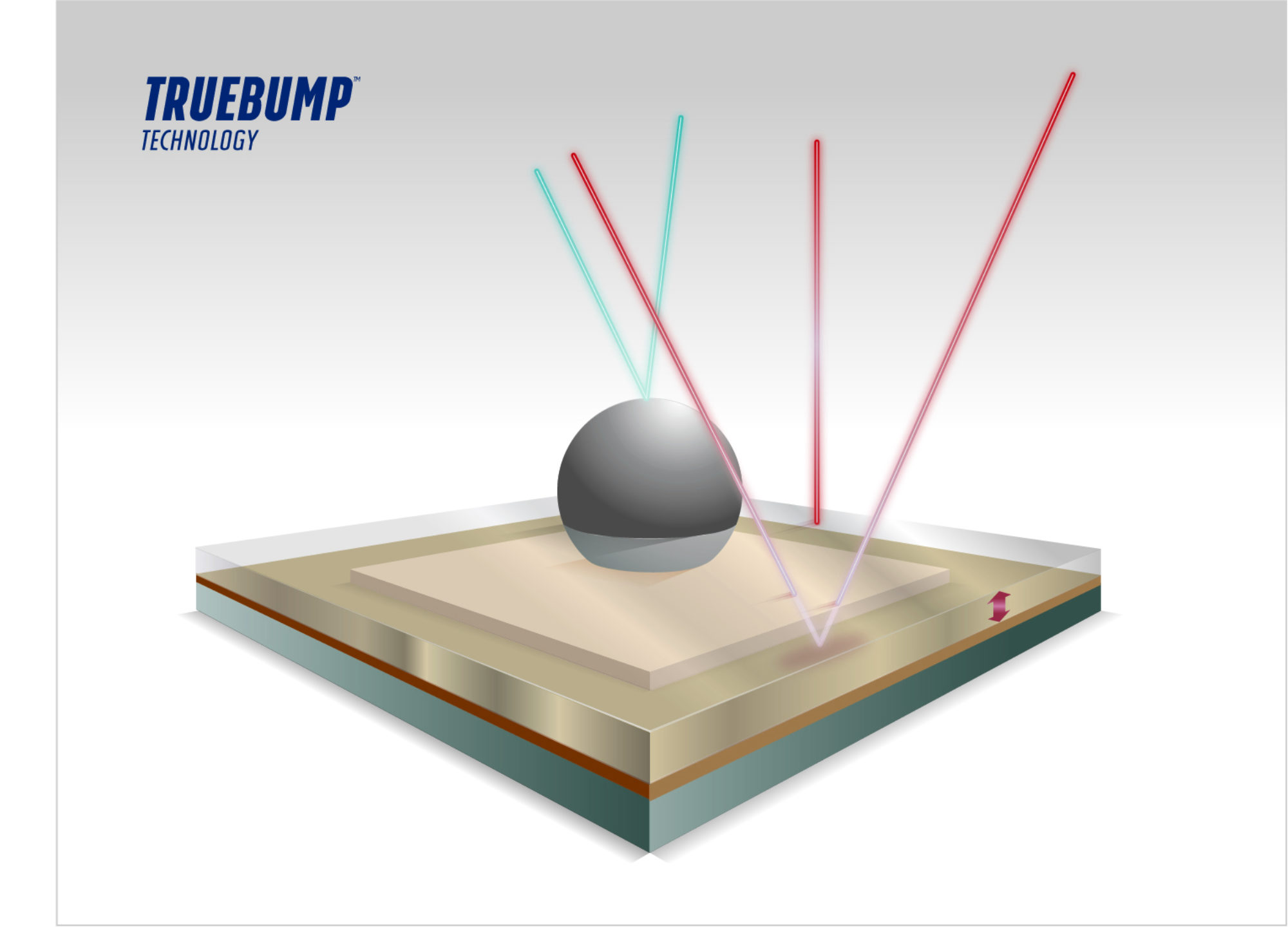

Onto Innovation enables this with our Truebump® Technology to accurately measure 3D bump features on devices. Truebump Technology is available on the Dragonfly Inspection System.

When stacking multiple devices to increase functionality, the interconnects become the most critical aspect of quality. Because those connections are so vital, the 3D bump measurements need to be absolutely accurate.

Truebump Technology combines multiple 3D metrology techniques that deliver industry-changing performance for measuring 100% bump height on wafers at speeds that have not been possible until now. Whether measuring copper pillar bumps, micro bumps, or large C4 bumps, confirming the coplanarity of the bumps on a device is paramount to device reliability.

High-speed, accurate bump measurements are achieved with a short wavelength laser and a proprietary sensor that collects data at extremely high data rates. Multiple objectives with programmable stray light control enhances application-specific capabilities. Scanning large bumps with one pass is accomplished with a high depth of focus.

A single wafer may contain millions of bumps, each with multiple data points for height, diameter, location, and more. The massive amounts of data generated during inspection can be overwhelming to analyze. The Dragonfly system’s integrated Discover® Defect Software gives users the analytical tools to visualize data, correct coplanarity variations, and improve yields.

Final package failures are costly. Improved accuracy and repeatability are needed as bump sizes continue to decrease and the number of stacked devices increases.

We live in a smart, connected world. The reliability of connected devices is expected, and that’s why device manufacturers rely on Onto Innovation for process control… helping to ensure that our connected world is working as it should, when it should.