Product Overview

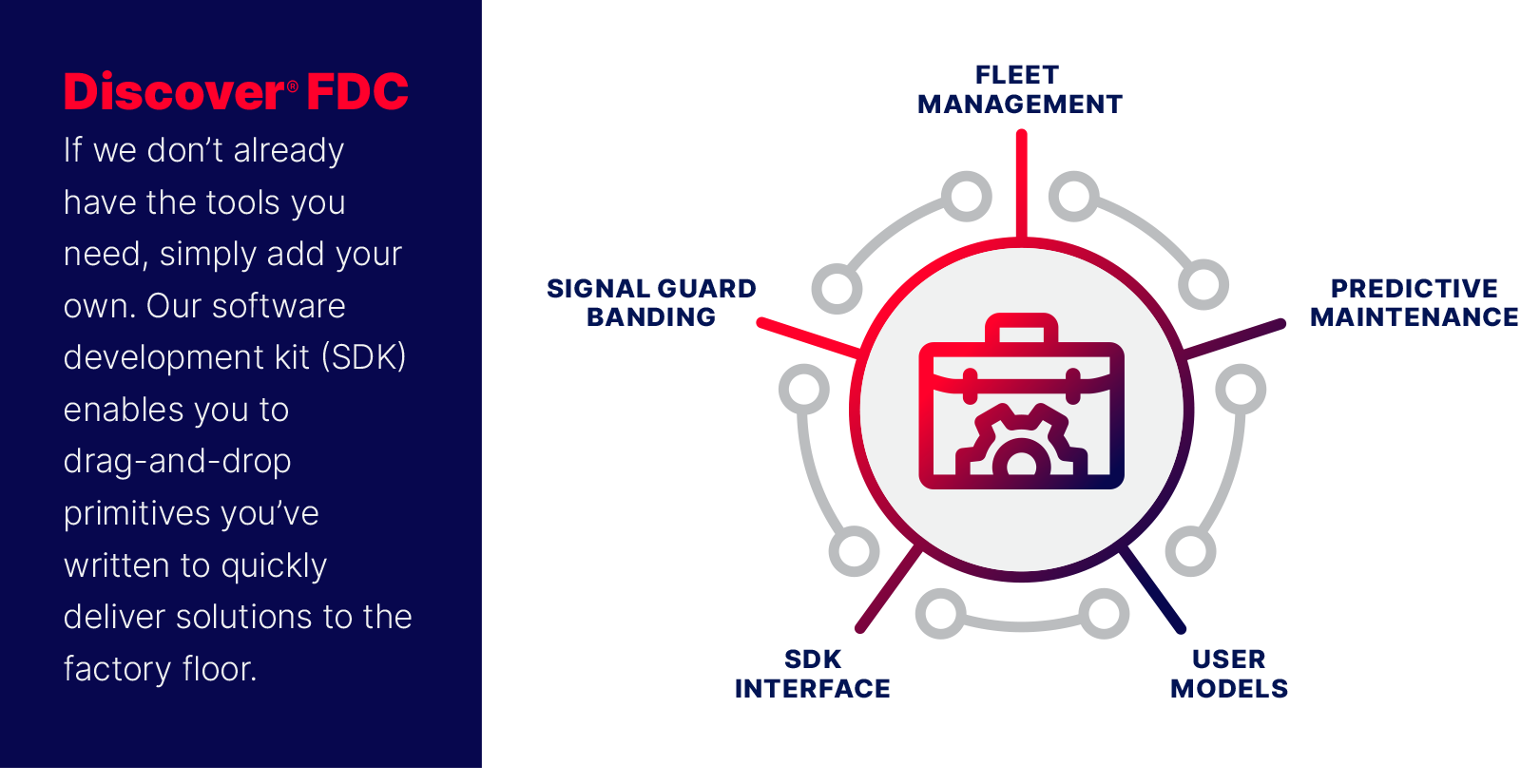

Where do you want to take control? Start by turning your tool and IoT data into actionable information. That’s where Discover FDC comes in. A foundational step to achieving Industry 4.0, Discover FDC converts your data into a complete, customizable factory snapshot. Onto Innovation’s fault detection and classification tool kit contains a diverse set of flexible controls to address your unique needs. No black box solutions here. It’s the control engineer’s preferred control solution.

Discover FDC has been proven across all processes and operation modules to enable maximum, enterprise-wide factory efficiency. The integrated user interface correlates key advanced process control and yield management system metrics. Scaling to high volume manufacturing with ease, Discover FDC manages and analyzes huge volumes of data in real-time to recognize tool fails. By interrupting the tool when anomalies are detected, they can’t grow into a much larger problem.

Pinpointing a problematic tool mechanism to bring equipment online faster, Discover FDC increases equipment availability (OEE) through reduced labor costs and dramatically improved cycle time. No time or energy is wasted on idle tools or scrapped wafers. That’s control.

When connected to Discover Defect and Discover Yield systems, Discover FDC software highlights meaningful correlations that further maximize production revenues.

Applications

• Memory

• Logic

• Microprocessor

• ASIC

• Foundry

• Compound-Semi

• HDD

• LED

• Advanced Packaging

• Panel / MCM

Selected Papers and Articles

Related Products & Markets

Discover Run-to-Run Software

Targeting the sweet spot for your smart factory

Discover Defect Software

Greater visibility to drive your smart factory to a cleaner operation

Advanced Packaging

Issues during die singulation can result in chips and cracks that impact the long-term reliability of devices.